品 名:机械密封

适用范围:化工泵、清水泵、污水泵、废水泵、油泵

适用行业:炼钢、造纸、化工、电力、水泥行业等

结构特点:

1.单端面,橡胶波纹管补偿,抗堵塞能力强。使用时,不分弹簧旋向。

2.辅助密封圈为丁腈橡胶、氟橡胶、乙丙橡胶、硅橡胶。

3.符合ISO3069、DIN24960和GB6556标准,通用性强。

适用介质:

油、水、酸、碱、盐等清水及含有颗粒废水、污水、污油中。

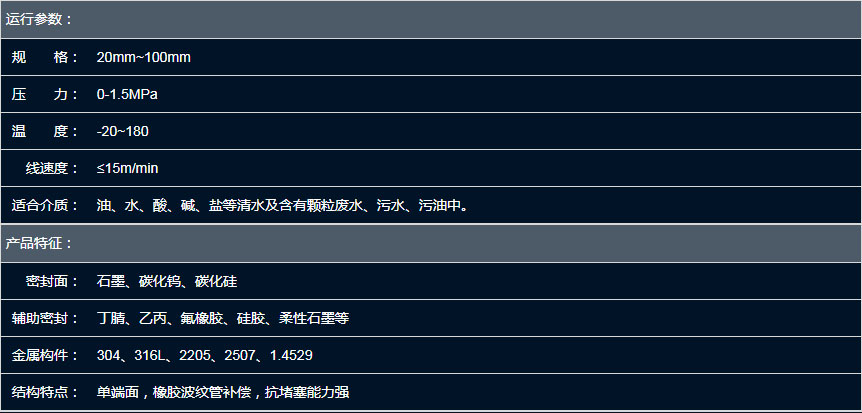

工作参数:

固定物含量:≤10%

温 度:≤180℃

压 力:≤1.5MPa

轴 径:≤100mm

材质参数:

主体材质:304、316L或2205、2507、1.4529

密封环材质:石墨、碳化硅、碳化钨

主要应用:

此型机械密封主要用于各类水泵、化工泵、污水泵、废水泵、污油泵。

常见型号:

KQW40/90-0.37/2 KQW40/100-0.55/2

KQW40/110-0.75/2 KQW40/125-1.1/2

KQW40/140-1.1/2 KQW40/150-1.5/2

KQW40/160-2.2/2 KQW40/170-2.2/2

KQW40/185-3/2 KQW40/200-4/2

KQW40/220-4/2 KQW40/235-5.5/2

KQW40/250-7.5/2 KQW50/90-0.75/2

KQW50/100-1.1/2 KQW50/160-3/2

KQW50/110-1.1/2 KQW50/125-1.5/2

KQW50/140-1.5/2 KQW50/150-2.2/2

KQW50/170-3/2 KQW50/185-4/2

KQW50/200-5.5/2 KQW50/220-7.5/2

KQW50/235-7.5/2 KQW65/125-3/2

KQW50/250-11/2 KQW65/90-1.1/2

KQW65/100-1.5/2 KQW65/110-2.2/2

KQW65/140-3/2 KQW65/150-4/2

KQW65/160-4/2 KQW65/170-5.5/2

KQW65/185-7.5/2 KQW65/270-15/2

KQW65/200-7.5/2 KQW65/220-11/2

KQW65/235-11/2 KQW65/250-15/2

KQW65/285-18.5/2 KQW65/300-22/2

KQW65/315-30/2 KQW80/90-2.2/2

KQW80/100-3/2 KQW80/160-7.5/2

KQW80/110-4/2 KQW80/125-5.5/2

KQW80/140-5.5/2 KQW80/150-7.5/2

KQW80/170-7.5/2 KQW80/185-11/2

KQW80/200-15/2 KQW80/220-15/2

KQW80/235-18.5/2 KQW80/315-37/2

KQW80/250-22/2 KQW80/270-22/2

KQW80/285-30/2 KQW80/300-30/2

KQW100/90-4/2 KQW100/100-5.5/2

KQW100/110-7.5/2 KQW100/125-11/2

KQW100/140-11/2 KQW100/200-22/2

KQW100/150-11/2 KQW100/160-15/2

KQW100/170-15/2 KQW100/185-18.5/2

KQW100/220-30/2 KQW100/250-37/2

KQW100/235-30/2 KQW100/270-37/2

KQW100/285-45/2 KQW125/110-11/2

KQW100/300-55/2 KQW100/315-75/2

KQW125/90-7.5/2 KQW125/100-11/2

KQW125/125-15/2 KQW125/140-15/2

KQW125/150-18.5/2 KQW125/160-22/2

KQW125/170-22/2 KQW125/250-55/2

KQW125/185-30/2 KQW125/200-37/2

KQW125/220-37/2 KQW125/235-45/2

KQW125/270-55/2 KQW125/285-75/2

KQW125/300-75/2 KQW125/315-90/2

KQW125/320-15/4 KQW150/200-15/4

KQW125/345-18.5/4 KQW125/370-22/4

KQW125/400-30/4 KQW150/185-11/4

KQW150/220-11/4 KQW150/235-15/4

KQW150/250-18.5/4 KQW150/285-18.5/4

KQW150/300-22/4 KQW150/400-45/4

KQW150/315-30/4 KQW150/320-22/4

KQW150/345-30/4 KQW150/370-37/4

KQW150/410-55/4 KQW150/435-75/4

KQW150/460-75/4 KQW200/185-15/4(Z)

KQW200/200-18.5/4(Z) KQW200/300-37/4(Z)

KQW200/220-15/4(Z) KQW200/235-18.5/4(Z)

KQW200/250-30/4(Z) KQW200/285-30/4(Z)

KQW200/315-45/4(Z) KQW200/320-37/4(Z)

KQW200/345-45/4(Z) KQW200/370-55/4(Z)

KQW200/400-75/4(Z) KQW250/250-45/4

KQW200/410-75/4(Z) KQW200/435-90/4(Z)

KQW200/460-110/4(Z) KQW250/235-37/4

KQW250/300-55/4 KQW250/315-75/4

KQW250/345-75/4 KQW250/370-90/4

KQW250/400-110/4 KQW300/485-90/6

KQW300/375-45/6 KQW300/410-55/6

KQW300/425-55/6 KQW300/450-75/6

KQW300-200A-45/4 KQW300-200-55/4

KQW300-315B-55/4 KQW300-315A-75/4

KQW300-315-90/4 KQW350-315B-110/4

KQW300-400C-75/4 KQW300-400B-90/4

KQW300-400A-110/4 KQW300-400-132/4

KQW350-315A-132/4 KQW350-315B-90/4(Z)

KQL40/90-0.37/2 KQL40/100-0.55/2

KQL40/110-0.75/2 KQL40/125-1.1/2

KQL40/140-1.1/2 KQL40/150-1.5/2

KQL40/160-2.2/2 &nnbsp; KQL40/170-2.2/2

KQL40/185-3/2 KQL40/200-4/2

KQL40/220-4/2 KQL40/235-5.5/2

KQL40/250-7.5/2 KQL50/90-0.75/2

KQL50/100-1.1/2 KQL50/160-3/2

KQL50/110-1.1/2 KQL50/125-1.5/2

KQL50/140-1.5/2 KQL50/150-2.2/2

KQL50/170-3/2 KQL50/185-4/2

KQL50/200-5.5/2 KQL50/220-7.5/2

KQL50/235-7.5/2 KQL65/125-3/2

KQL50/250-11/2 KQL65/90-1.1/2

KQL65/100-1.5/2 KQL65/110-2.2/2

KQL65/140-3/2 KQL65/150-4/2

KQL65/160-4/2 KQL65/170-5.5/2

KQL65/185-7.5/2 KQL65/270-15/2

KQL65/200-7.5/2 KQL65/220-11/2

KQL65/235-11/2 KQL65/250-15/2

KQL65/285-18.5/2 KQL65/300-22/2

KQL65/315-30/2 KQL80/90-2.2/2

KQL80/100-3/2 KQL80/160-7.5/2

KQL80/110-4/2 KQL80/125-5.5/2

KQL80/140-5.5/2 KQL80/150-7.5/2

KQL80/170-7.5/2 KQL80/185-11/2

KQL80/200-15/2 KQL80/220-15/2

KQL80/235-18.5/2 KQL80/315-37/2

KQL80/250-22/2 KQL80/270-22/2

KQL80/285-30/2 KQL80/300-30/2

KQL100/90-4/2 KQL100/100-5.5/2

KQL100/110-7.5/2 KQL100/125-11/2

KQL100/140-11/2 KQL100/200-22/2

KQL100/150-11/2 KQL100/160-15/2

KQL100/170-15/2 KQL100/185-18.5/2

KQL100/220-30/2 KQL100/250-37/2

KQL100/235-30/2 KQL100/270-37/2

KQL100/285-45/2 KQL125/110-11/2

KQL100/300-55/2 KQL100/315-75/2

KQL125/90-7.5/2 KQL125/100-11/2

KQL125/125-15/2 KQL125/140-15/2

KQL125/150-18.5/2 KQL125/160-22/2

KQL125/170-22/2 KQL125/250-55/2

KQL125/185-30/2 KQL125/200-37/2

KQL125/220-37/2 KQL125/235-45/2

KQL125/270-55/2 KQL125/285-75/2

KQL125/300-75/2 KQL125/315-90/2

KQL125/320-15/4 KQL150/200-15/4

KQL125/345-18.5/4 KQL125/370-22/4

KQL125/400-30/4 KQL150/185-11/4

KQL150/220-11/4 KQL150/235-15/4

KQL150/250-18.5/4 KQL150/285-18.5/4

KQL150/300-22/4 KQL150/400-45/4

KQL150/315-30/4 KQL150/320-22/4

KQL150/345-30/4 KQL150/370-37/4

KQL150/410-55/4 KQL150/435-75/4

KQL150/460-75/4 KQL200/185-15/4(Z)

KQL200/200-18.5/4(Z) KQL200/300-37/4(Z)

KQL200/220-15/4(Z) KQL200/235-18.5/4(Z)

KQL200/250-30/4(Z) KQL200/285-30/4(Z)

KQL200/315-45/4(Z) KQL200/320-37/4(Z)

KQL200/345-45/4(Z) KQL200/370-55/4(Z)

KQL200/400-75/4(Z) KQL250/250-45/4

KQL200/410-75/4(Z) KQL200/435-90/4(Z)

KQL200/460-110/4(Z) KQL250/235-37/4

KQL250/300-55/4 KQL250/315-75/4

KQL250/345-75/4 KQL250/370-90/4

KQL250/400-110/4 KQL300/485-90/6

KQL300/375-45/6 KQL300/410-55/6

KQL300/425-55/6 KQL300/450-75/6

KQL300-200A-45/4 KQL300-200-55/4

KQL300-315B-55/4 KQL300-315A-75/4

KQL300-315-90/4 KQL350-315B-110/4

KQL300-400C-75/4 KQL300-400B-90/4

KQL300-400A-110/4 KQL300-400-132/4

KQL350-315A-132/4 KQL350-315B-90/4(Z)

注:由于泵用途较多,故密封材质(摩擦副)也有不同,为保证密封的使用可靠性

厂家推荐如下:

1.清水(不含颗粒物工况)--动环摩擦副选用(合金),静环摩擦副选用(石墨)

2.强腐蚀(含有颗粒物工况)--动环摩擦副选用(碳化硅),静环摩擦副选用(碳化硅)

3.含有颗粒且振动较大工况--动环摩擦副选用(合金),静环摩擦副选用(合金)

4.也可以根据客户要求定做。如没有要求则默认为(清水)

安装使用要求:

1、设备转轴的径向跳动应不大于0.04毫米,轴向窜动量不允许大于0.1毫米;

2、设备的密封腔部位在安装时应保持清洁,密封零件应进行清洗,密封端面完好无损,防止杂质和灰尘带入密封部位;

3、在安装过程中严禁碰击、敲打,以免使机械密封磨擦会破损而密封失效;

4、安装时在与密封相接触的表面应涂一层清洁的机械油,以便能顺利安装;

5、安装静环压盖时,拧紧螺丝必须受力均匀,保证静环端面与轴心线的垂直要求;

6、安装后用手推动动环,能使动环在轴上灵活移动,并有一定弹性;

7、安装后用手盘动转轴,转轴应无轻重感觉;

8、设备在运转前必须充满介质,以防止干磨擦而使密封失效;